From Automation Fears to Workforce Expansion

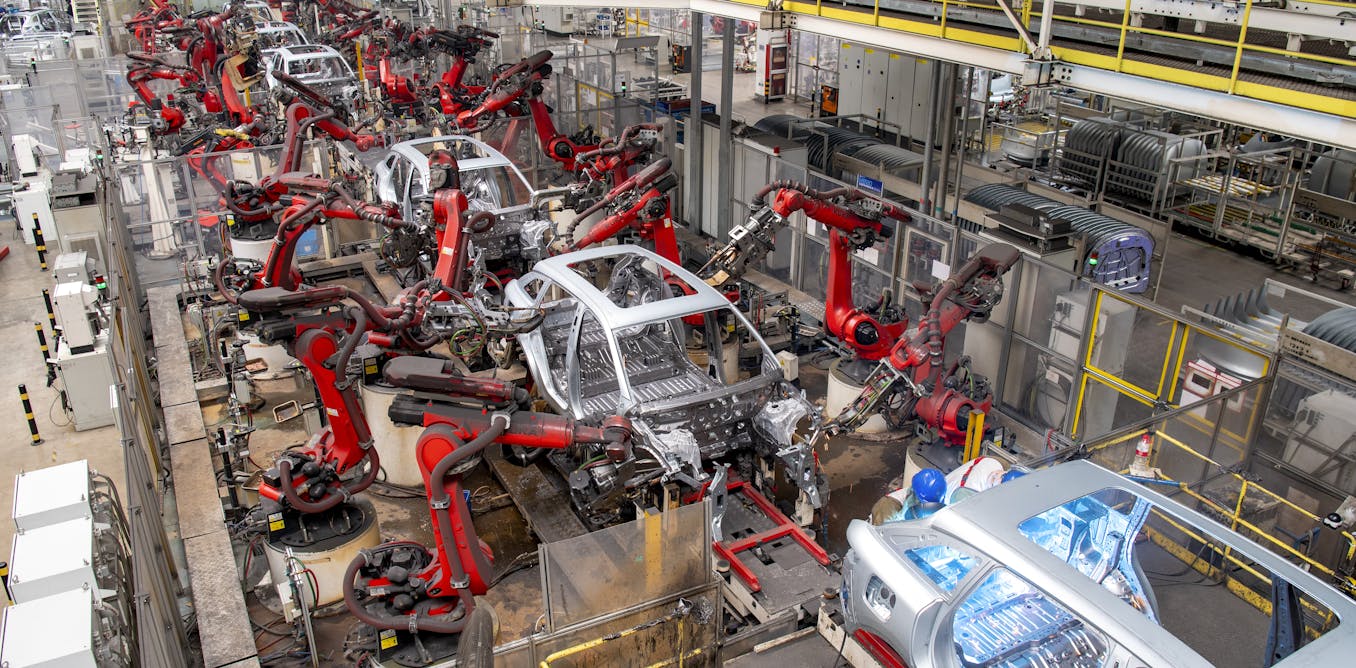

When Priestley’s Gourmet Delights made the game-changing decision to automate its business, some wondered whether it would mean job losses. Instead, the Brisbane-based company went on to expand its workforce.

"We moved to a brand new automated site 18 months ago and we have actually increased headcount since we got here," Priestley’s CEO and MD Xanny Christophersen said.

"The focus has been on creating a better experience for our people because even with automation, every product is still hand-finished with care and made with love."

A True Australian Success Story

Priestley’s is a bona fide Australian success story. Based at new premises in Acacia Ridge, in Brisbane’s south, the business started out small in 1996 by distributing cakes in Milton, Queensland.

Since those humble beginnings, Priestley’s has grown into a national baking giant, supplying products to 27,000 cafes around Australia. When customers buy a sweet treat from a local café, they are also supporting their 200-plus employees.

Each week, the business bakes a massive 270,000 units of sweet and savoury cake, including cheesecakes, muffins, cookies, lamingtons, pavlovas and quiches.

Family Roots and Local Sourcing

"Cake is in my blood. I’ve been in the business since I was seven. I did spend a few years in finance in the UK, but somehow, I always found my way back to cake," Ms Christophersen said.

"I remember being a kid and driving around with my Aunt Marilyn delivering cakes on the Sunshine Coast.

"We are family owned and operated. We source local goods and services whenever we can, including Bundaberg sugar, carrots from Kalbar and toppings from Trisco Foods which is close by. We have also had a long association with Sunny Queen Eggs.

"Our philosophy is that we never lose – we either win or we learn. We don’t stand still, we are always asking ‘what if?’ and striving for more."

Built on Partnerships and Shared Values

Priestley’s success has been built on "partnerships and shared values".

"For us, it’s about working as one team, always striving to do better, especially when it comes to sustainability, doing what’s right, and keeping safety at the heart of everything we do," Ms Christophersen said.

Government Support and Competitive Edge

A Westpac spokesperson said Priestley’s Gourmet Delights’ AI driven factory had given them a competitive business edge.

"As soon as we heard their plans we knew it would be a game-changer, so we connected Priestley’s with our network of experts to help them apply for a Made In Queensland grant," the spokesperson said.

"They ultimately received $2.5 million from the Queensland Government, enabling them to purchase automation equipment and create at least 21 new jobs."

Comments

Join Our Community

Sign up to share your thoughts, engage with others, and become part of our growing community.

No comments yet

Be the first to share your thoughts and start the conversation!